TDS (Technical Data Sheet) is a document that provides information about a product’s technical properties, such as its physical and chemical characteristics, usage guidelines, and performance details. It is used to help customers understand how to use the product effectively.

SDS (Safety Data Sheet) is a document that focuses on safety and regulatory information. It outlines the hazards associated with a product, how to handle it safely, and what to do in case of an emergency. SDS is required for products that are classified as hazardous.

Product Specifications: Details on the physical and chemical properties of the product, such as density, viscosity, and composition.

Usage Instructions: Guidelines on how to apply, mix, or use the product for optimal performance.

Performance Characteristics: Information on the expected results, such as durability, efficiency, or compatibility with other materials.

Storage Recommendations: Advice on how to store the product to maintain its effectiveness.

Technical Compliance: Certifications or standards the product meets, ensuring it is suitable for specific applications.

Hazard Identification: Information on the potential risks associated with the product, including health hazards, environmental impact, and physical dangers.

Safety Precautions: Detailed instructions on how to handle, store, and dispose of the product safely.

First-Aid Measures: Step-by-step guidance on what to do in case of exposure or accidents involving the product.

Fire-Fighting Measures: Instructions on how to handle fires involving the product, including suitable extinguishing methods.

Regulatory Information: Compliance with local, national, and international safety regulations, ensuring legal handling and use of the product.

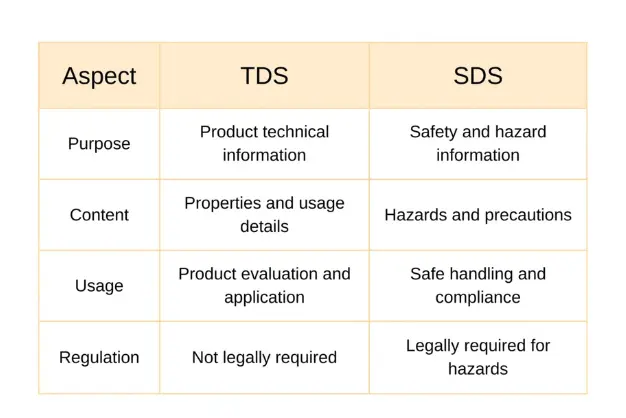

In summary, a TDS focuses on technical and application-related details, while an SDS concentrates on safety, health, and regulatory aspects. Both documents are essential, but they serve different purposes depending on the needs of the user.

TDS (Technical Data Sheet): The main objective of a TDS is to provide detailed technical information about a product. It explains the product’s properties, performance capabilities, and how it should be used in various applications. TDS is intended to help users make informed decisions about product selection and application. SDS (Safety Data Sheet): The purpose of an SDS is to communicate safety information. It outlines the hazards associated with a product, provides instructions for safe handling, and explains what to do in case of an emergency. SDS is crucial for ensuring the safety of those who handle or come into contact with the product. TDS: Includes technical details like product composition, physical and chemical properties, application guidelines, and performance data. It might also cover storage recommendations and any compliance with industry standards. SDS: Contains safety-related information such as hazard identification, safety precautions, first-aid measures, and fire-fighting instructions. It also includes details on proper storage, handling, and disposal, along with regulatory compliance information. TDS: Used primarily by engineers, product managers, and end-users who need to understand the technical aspects of a product to determine its suitability for specific applications. SDS: Utilized by safety officers, regulatory agencies, and anyone responsible for the safe handling, storage, and disposal of potentially hazardous materials. TDS: There are no specific legal obligations tied to the creation of a TDS, but it is often provided by manufacturers to assist customers in making informed choices about their products. SDS: Strictly regulated by various national and international laws, such as OSHA’s Hazard Communication Standard in the U.S. An SDS is legally required for any product classified as hazardous, ensuring that the necessary safety information is available to protect workers and the environment. Appropriate for Product Selection: A TDS is used when you need to understand the technical properties of a product, such as its composition, performance characteristics, and suitability for specific applications. It helps in making informed decisions about which product to choose based on technical needs.

Application Guidance: If you’re working on a project that requires specific application instructions, such as mixing ratios, curing times, or compatibility with other materials, the TDS will provide the necessary details to ensure successful use.

Required for Safety and Compliance: An SDS is required whenever you are handling, storing, or transporting a product that could pose a risk to health, safety, or the environment. It provides critical information on how to manage potential hazards safely.

Regulatory Situations: If you are dealing with products classified as hazardous under regulations like OSHA’s Hazard Communication Standard, an SDS is legally required. It ensures that all safety protocols are followed to protect workers and comply with the law.

Using a TDS: If you’re selecting a sealant for a construction project, you would refer to the TDS to understand the product’s adhesive strength, curing time, and compatibility with different materials.

Using an SDS: If you’re working in a lab with chemicals, you would need the SDS to know how to safely handle the chemicals, what protective equipment to use, and what to do in case of exposure or spillage.

Clarification: One common misunderstanding is that TDS and SDS can be used interchangeably because they both provide information about a product. In reality, they serve very different purposes. A TDS focuses on the technical aspects of a product, while an SDS is dedicated to safety information. Using one in place of the other can lead to incomplete or inappropriate handling of the product.

Clarification: Another misconception is that a TDS includes all the safety information needed for handling a product. While a TDS might briefly touch on safe usage, it does not provide the comprehensive safety data found in an SDS. Relying solely on a TDS for safety guidance can be dangerous, especially with hazardous materials.

Clarification: Some believe that an SDS is only required for chemicals or products that are overtly hazardous. While it’s true that SDS is legally mandated for hazardous products, it is also useful for any product where safety precautions are necessary. This ensures that anyone handling the product is fully informed about potential risks.

Clarification: There is a misconception that providing a TDS is enough to meet regulatory compliance. However, regulatory bodies often require an SDS for products that pose any risk. The TDS alone does not fulfill legal requirements for safety documentation.

Ensuring Product Safety and Effectiveness: The TDS and SDS serve complementary roles in the industry, ensuring that products are used safely and effectively. The TDS provides users with the technical details they need to optimize the product’s performance, such as mixing ratios, application methods, and environmental conditions. On the other hand, the SDS offers critical safety information, detailing how to handle, store, and dispose of the product safely. Together, these documents ensure that users have all the information necessary to achieve the desired results without compromising safety.

Regulatory Compliance: Both the TDS and SDS are vital for regulatory compliance. The SDS is particularly important as it is often required by law for products classified as hazardous, ensuring that safety protocols are followed in the workplace. The TDS, while not always legally required, supports compliance by providing the technical specifications that help in meeting industry standards and regulations.

Quality Assurance: These documents also play a key role in quality assurance. The TDS ensures that the product is used in the right way to achieve the best possible outcome, while the SDS ensures that it is used safely. By providing clear and accurate information, these documents help maintain consistency in product use and safety, which is essential for quality control in manufacturing, construction, and other industries.