Industrial Machinery: Ensuring Reliability

At RawSource, we’re committed to enhancing the performance and reliability of your industrial machinery.

Elevating Performance

Our innovative solutions are designed to withstand the rigors of heavy-duty operations and ensure seamless functionality in demanding environments. From advanced lubricants to protective coatings, RawSource has the right products to keep your machinery running smoothly.

Silicone Greases with PDMS and Lithium Soaps

At lower pressure levels, PDMS (polydimethylsiloxane) or non-reactive methyl phenyl oils are typically blended with lithium soaps to create silicone greases that excel in terms of efficiency. These specially formulated silicone greases offer highly effective lubrication in both dynamic and static situations, while also maintaining their viscosity over a broad temperature range.

Advanced Lubrication

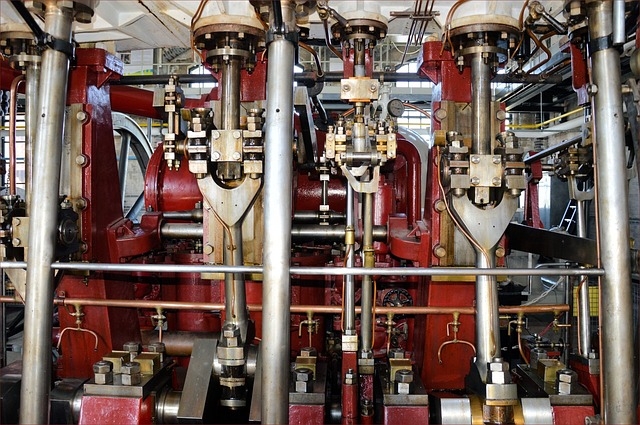

Efficient lubrication is paramount for optimal machinery performance. RawSource offers a range of high-quality lubricants that minimize friction, reduce wear and tear, and extend the lifespan of critical components. Our advanced lubrication solutions are formulated to excel even in extreme temperatures and heavy loads, making them ideal for various industrial machinery applications.

Bearings and gears

Motors and drives

Chains and sprockets

Protective Coatings

Industrial machinery often faces exposure to corrosive substances, abrasion, and mechanical stress. RawSource’s protective coatings act as a shield, safeguarding your equipment from harsh conditions and preventing premature deterioration. Our coatings provide exceptional resistance to chemicals, impact, and wear, ensuring your machinery remains reliable and operational.

Equipment exposed to chemicals or acids

Machinery operating in outdoor environments

Standing out in a competitive Components vulnerable to abrasion and erosion

Contact RawSource today to discover how our specialized solutions can optimize the reliability and performance of your industrial machinery.