Antifoams

Discover the power of RawSource’s antifoam solutions in eliminating foam-related challenges across various industries.

Antifoams Solutions: Effortless Defoaming with RawSource Specialty Chemicals

Our innovative antifoams agents are designed to prevent and control foam formation, improving process efficiency and product quality. Say goodbye to foam-induced bottlenecks and hello to seamless operations with RawSource’s effective and reliable antifoams products.

Product Description

RawSilTM 050E-AF is a versatile water based silicone antifoam emulsion with utility in many industrial applications where a highly efficient product with significant foam knockdown and good sustaining antifoam power is needed. RawSilTM 050E-AF is formulated to withstand cold temperature storage.

Antifoam Silicone Fluids in Oil and Gas Applications

Antifoam Silicone Fluids, also known as PDMS Silicone Oils, is a versatile group of polydimethylsiloxane fluids available in a viscosity range from 1,000cSt to 1,000,000cSt at 25°C. These fluids are highly regarded in the Oil and Gas industry for their exceptional ability to mitigate foam-related challenges during various production, refinery, and gas processing operations.

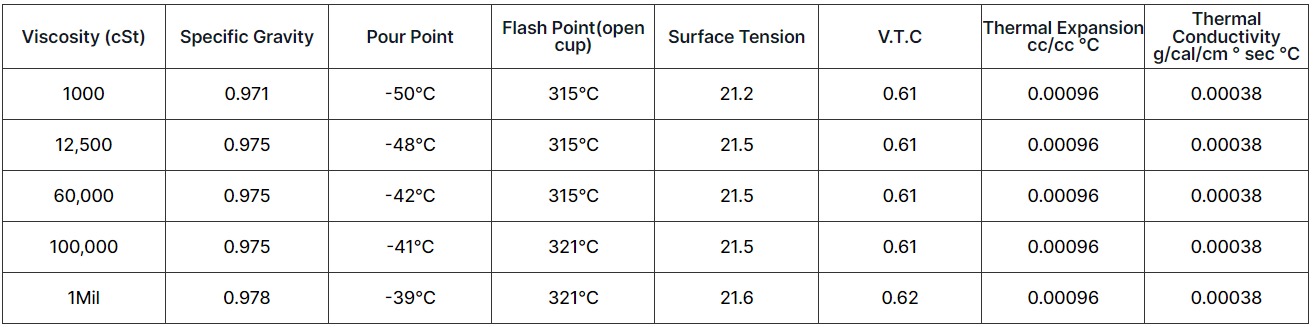

Product Data

Scroll

Viscosity

(cSt)

Specific Gravity

Pour Point

Flash Point(open cup)

Surface Tension

V.T.C

Thermal Expansion cc/cc °C

Thermal Conductivity g/cal/cm ° sec °C

1000

0.971

-50°C

315°C

21.2

0.61

0.00096

0.00038

12,500

0.975

-48°C

315°C

21.5

0.61

0.00096

0.00038

60,000

0.975

-42°C

315°C

21.5

0.61

0.00096

0.00038

100,000

0.975

-41°C

321°C

21.5

0.61

0.00096

0.00038

1Mil

0.978

-39°C

321°C

21.6

0.62

0.00096

0.00038

Key Characteristics of Antifoam Silicone Fluids

Hydrophobic Nature

These fluids are inherently hydrophobic, making them highly effective in applications where moisture control is critical. They prevent humidity from entering instrument housings, a particularly valuable trait in demanding environments.

Thermal Stability

With a wide service temperature range and high thermal stability, these silicone fluids maintain their effectiveness in extreme conditions, ensuring reliable performance even in harsh temperature fluctuations.

Resistance to Oxidation

They exhibit high resistance to oxidation, which is vital for maintaining product quality and longevity in a range of applications.

Low Viscosity Change at Temperature

PSF Antifoam Silicone Fluids experience minimal viscosity changes with temperature variations, ensuring consistent performance in dynamic environments.

High Flash Points

These fluids have high flash points, making them safe for use in various settings.

Low Vapor Pressure

With low vapor pressure, they minimize the risk of volatile emissions.

Stability at High Pressures

These fluids remain stable even under high-pressure conditions, such as downholes, drilling, and subsea operations.

Solubility

While they are insoluble in crude oil, PSF Antifoam Silicone Fluids are highly soluble in conventional solvents like toluene, xylene, diesel, or naphtha.

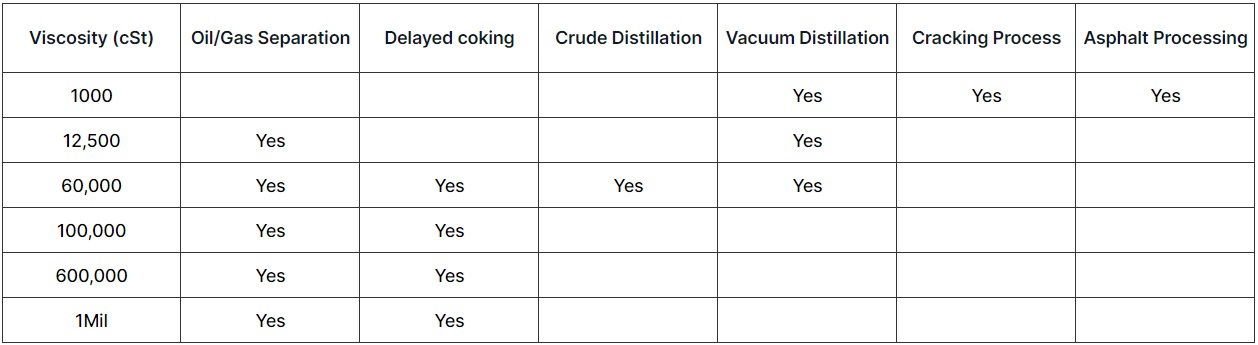

Fluid per Application in Oil & Gas / Refinery Operations

Scroll

Viscosity

(cSt)

Oil/Gas Separation

Delayed coking

Crude Distillation

Vacuum Distillation

Cracking Process

Asphalt Processing

1000

Yes

Yes

Yes

12,500

Yes

Yes

60,000

Yes

Yes

Yes

Yes

100,000

Yes

Yes

600,000

Yes

Yes

1Mil

Yes

Yes

Environmental Considerations

High Viscosity Silicone Fluids meet stringent environmental standards. They are exempt from Federal VOC regulations, including California (CARB) and OTC regulations. These fluids are HAP-free and do not contribute to ozone depletion or global warming. Furthermore, they are RoHS Compliant, aligning with modern environmental regulations.

Applications

High Viscosity Silicone Damping Fluids have a wide array of applications, including

- Pressure gauges

- Pressure control instruments

- Flow testing equipment

- Level controllers

- Subsea instruments

- Shock dampeners for R/C vehicles

- Underwater vehicles

- Liquid-filled gauges

- Geothermal monitoring equipment

- Process instruments

- Control valves

- Industrial thermometers

Antifoam Silicone Fluids excel in applications requiring dampening against vibration, sound, and amplitude of motion. Their hydrophobic nature and stability make them valuable across various industries, extending the service life of equipment and ensuring accuracy in challenging conditions.

These high-performance silicone fluids play a pivotal role in multiple sectors, including Oil & Gas, military, and industrial applications, where foam control, moisture resistance, and vibration dampening are paramount.

Taming Foam: RawSource's Effective Antifoams Agents

Experience hassle-free operations with RawSource’s highly effective antifoams agents. Our products are engineered to combat foam formation in diverse applications, including chemical processing, wastewater treatment, food and beverage production, and more. Prevent foam-induced inefficiencies and ensure smooth processes with RawSource’s cutting-edge antifoams solutions.

Controlling Foam in the Oil and Gas Industry

Harnessing the Potential of Silicone Antifoams in Oil and Gas

Drilling Operations

In drilling operations, foam can hinder drilling fluid performance and impact the overall efficiency of the drilling process. RawSource’s silicone antifoams are formulated to eliminate foam, ensuring that drilling operations proceed smoothly, minimizing downtime, and maximizing productivity.

Oil Production and Separation

Foaming issues can arise during oil production and separation processes, leading to reduced yields and operational disruptions. RawSource’s silicone antifoam agents are the solution, providing effective foam control to enhance oil recovery and separation efficiency.

Gas Processing

Gas processing facilities often encounter foam-related challenges during gas purification and treatment. RawSource’s silicone antifoams are designed to combat foam, optimizing gas processing operations and ensuring the purity of your end products.

The Role of Antifoams in Key Oil and Gas Processes

Enhancing Oil and Gas Operations with RawSource’s Antifoam Expertise

Water Treatment and Injection

Water treatment and injection are integral to oil and gas operations, but foam can hinder these processes. RawSource’s silicone antifoams ensure efficient water treatment and injection by preventing foam-related issues and maintaining the integrity of your water treatment systems.

Storage and Transportation

Foam can accumulate in storage tanks and disrupt transportation processes. RawSource’s silicone antifoams are your allies in these critical stages, guaranteeing smooth storage and transportation operations while safeguarding the quality of your stored or transported products.

Refinery Efficiency

Foaming challenges can affect refinery processes, impacting overall efficiency. RawSource’s silicone antifoam agents are engineered to optimize refinery operations, ensuring that your processes run smoothly, reducing downtime, and enhancing product quality.

Contact RawSource today to explore our comprehensive range of antifoams solutions and discover how our specialty chemicals can elevate your operations by conquering foam-related challenges. Let our antifoams products streamline your processes and enhance your productivity, ensuring smooth and efficient operations across industries.